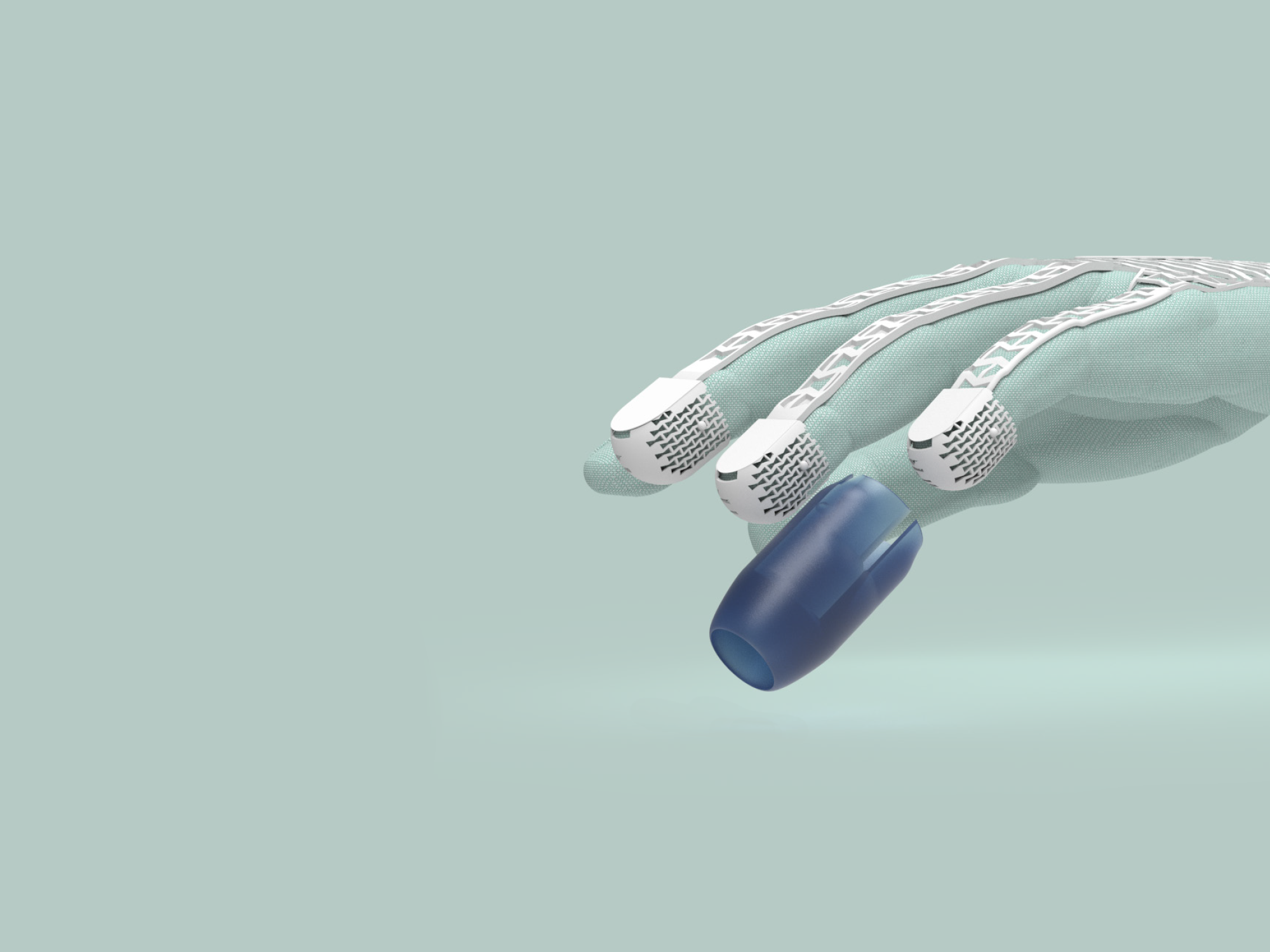

DePuy Synthes Surgical Glove

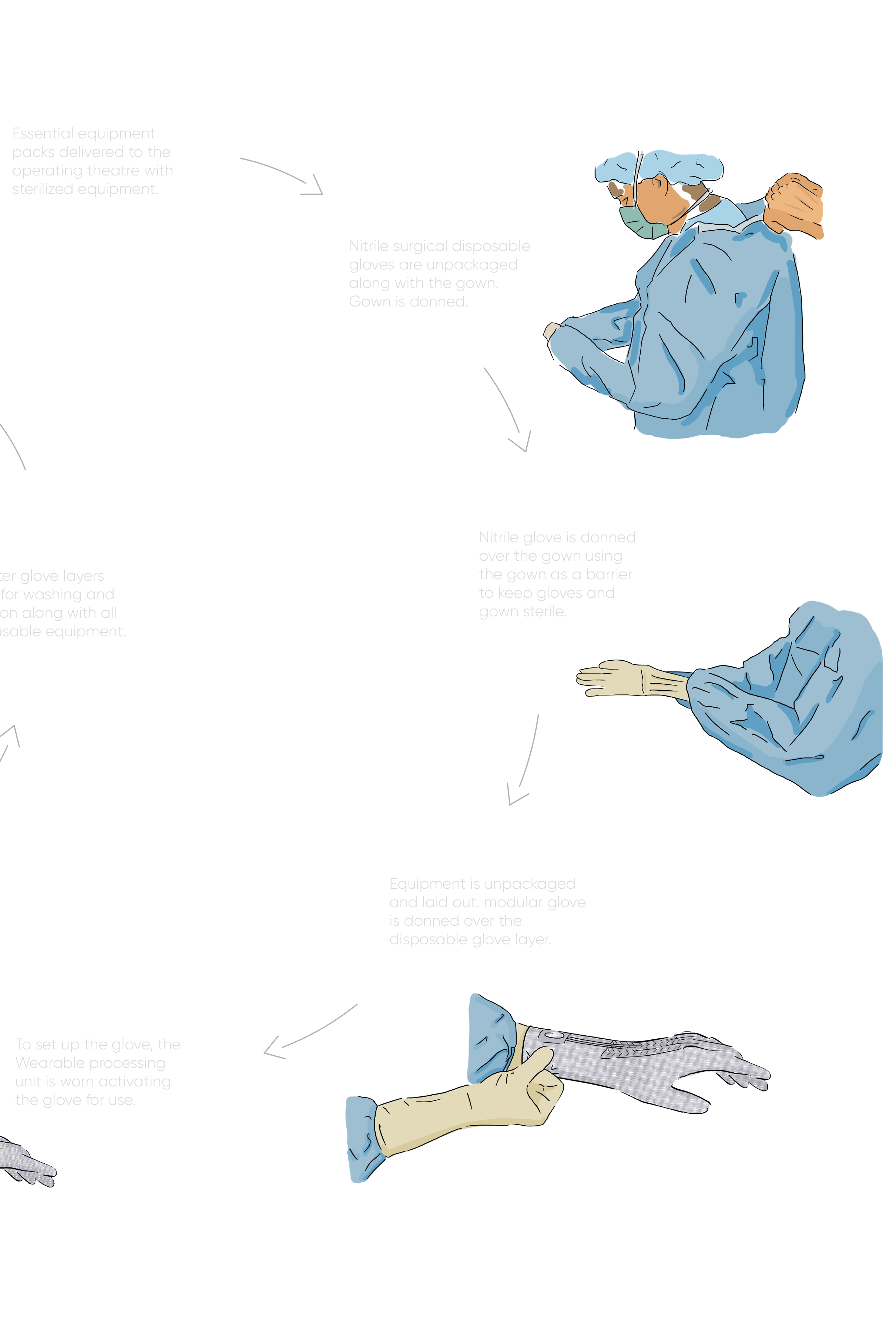

This project was drafted by DePuy Synthes, an expert in joint replacement, medical tooling and part of the Johnson & Johnson Medical Devices group. DePuy required a modular, cut-proof surgical glove to provide medical staff with greater functionality in the operating theatre. Our team offered a creative perspective to understand what could be possible within the scope of a glove.

The standard surgical glove has to adhere to numerous strict specifications. Primarily, and most importantly, it forms a sterile barrier between the surgeon and the patient. It must be chemically inert and easy to don, preserving both hand locomotion and finger dexterity. The project's main objectives were to identify suitable materials and determine what additional functions would be feasible in a non-intrusive glove design.

Project Type: Medical

Skills & Knowledge: Design process, Arduino programming, Material science, Leadership, Teamworking, Rapid prototyping, Testing, CAD, Client relationships, Presenting, Report Writing

A solution for a future of BIG data.

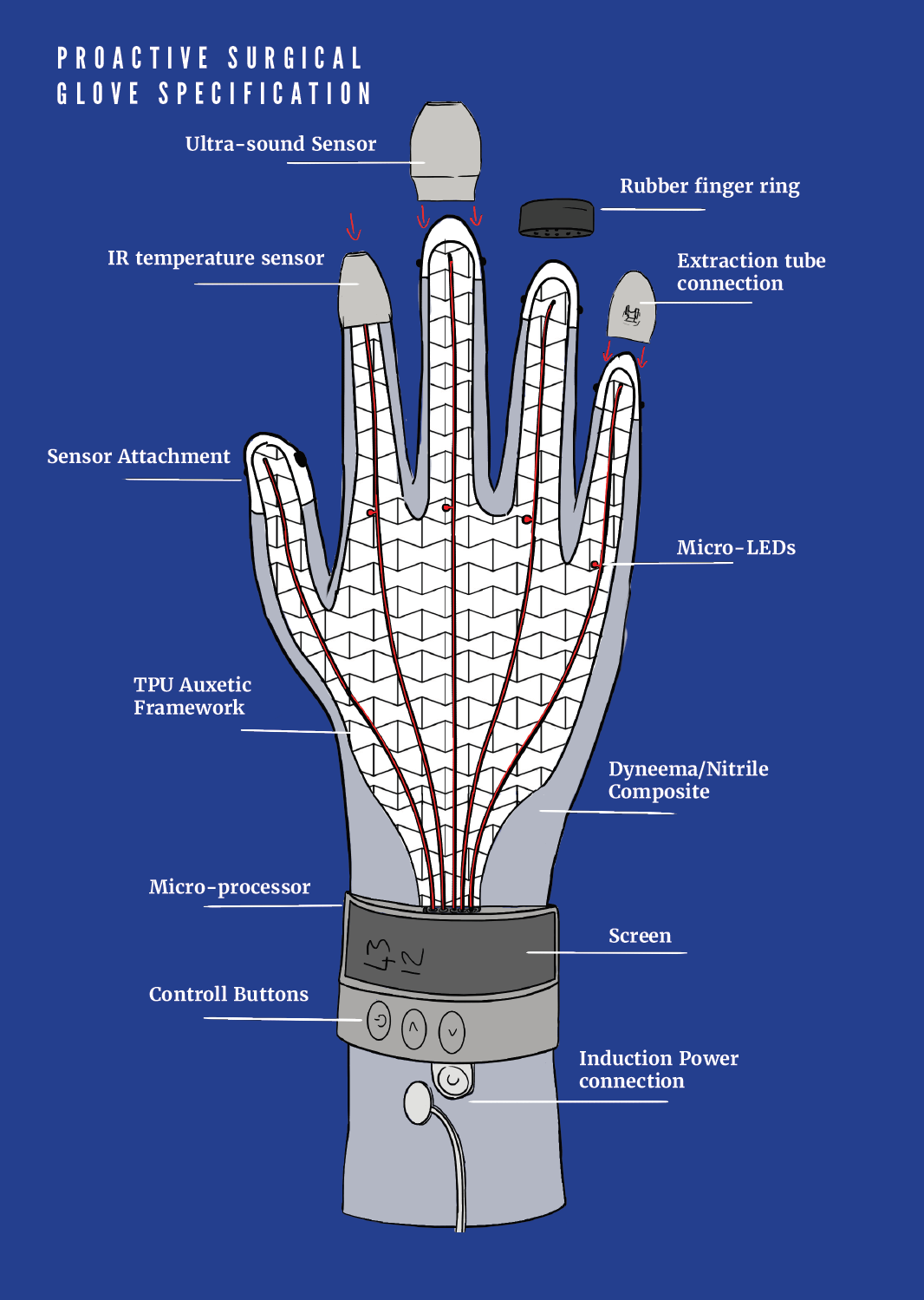

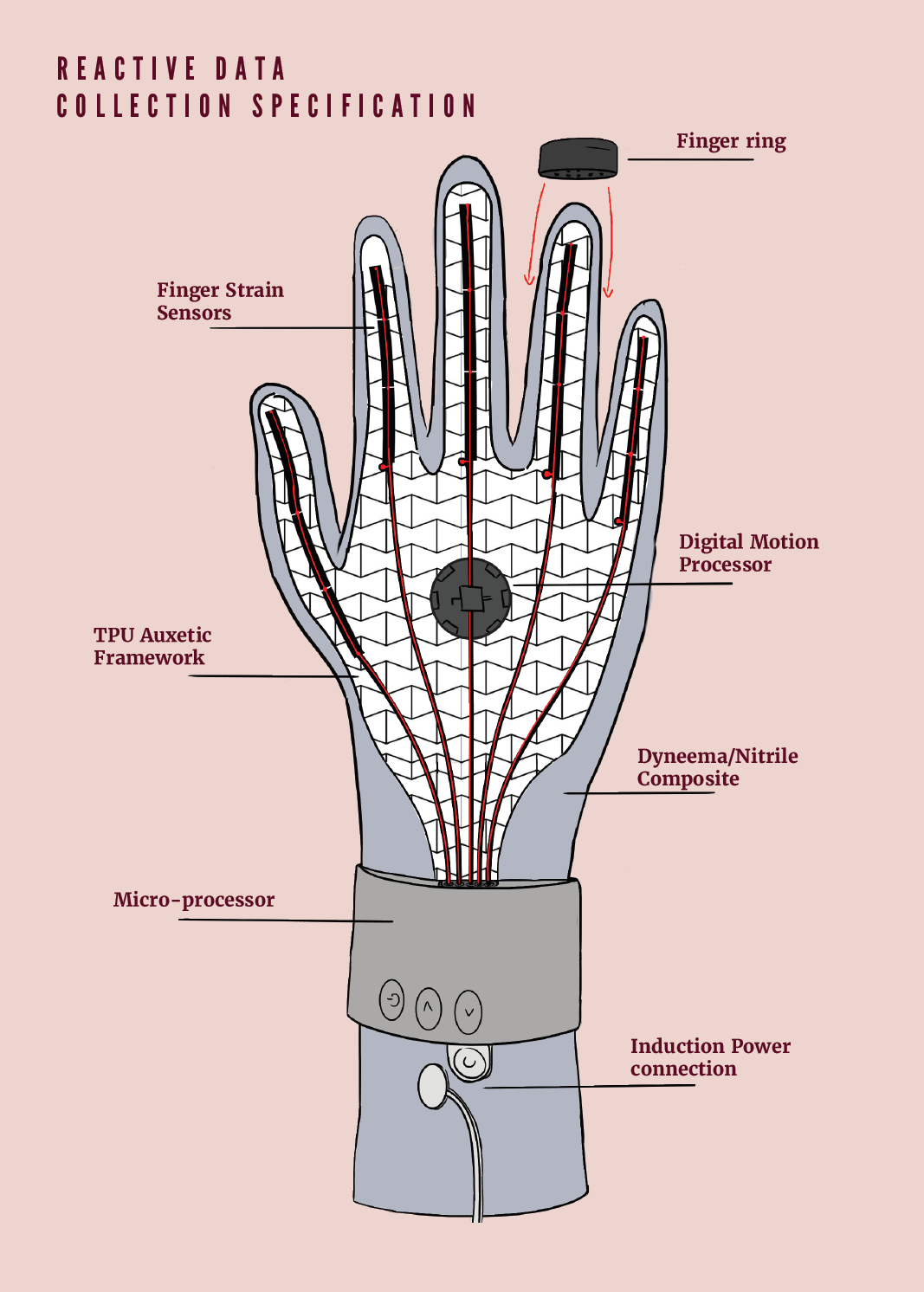

Tools and sensory devices enable surgeons to read a patient vitals. The glove is an opportunity to concentrate these surgical functions on the hand and visualise information with ease using instruments including, but not limited to, Ultrasound sensors, IR sensors or torchlight. The glove gathers sensory data in two principal ways. Firstly, removable sensors and tools attach to the fingers giving the surgeon real-time data to aid them in surgery. Secondly, locomotion sensors are embedded in the glove to record hand motion data for archiving and training applications post-surgery.

Collaborate towards product success.

Strong client relationships and teamwork were fundamental to the development process. Close and continuous contact with medical professionals proved vital in assessing the scope of the project, offering the team extensive knowledge of surgical responsibilities and medical innovations.

Regular meetings with the company were necessary to pitch ideas and aid in the development process. This required the team to manage our time efficiently and professionally to meet deadlines. Presenting and report writing skills were required to explain design choices. Skills in CAD editing software allowed us to convey ideas clearly and concisely through the use of 3D models and illustrations.

Materials turn concept,

into product.

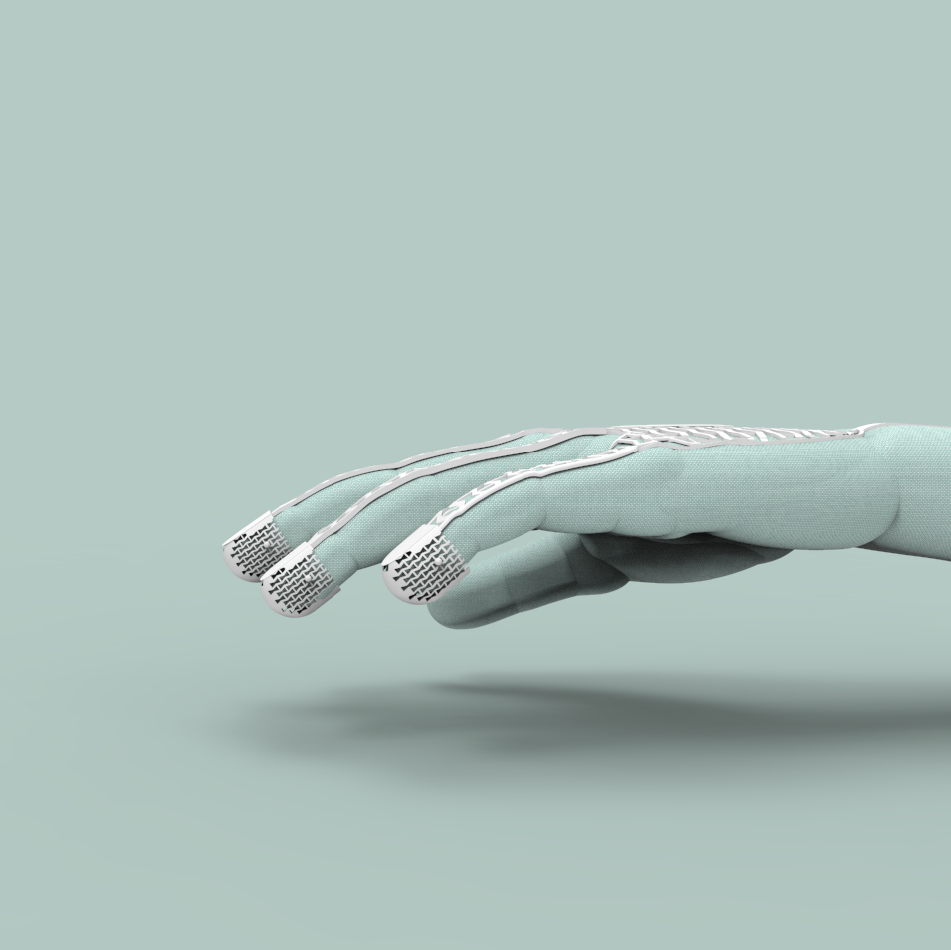

As a medical design project, technical knowledge of material science was essential throughout development. The team developed a flexible TPU auxetic pattern membrane with several design specifications in mind. Primarily, the membrane is required to house and protect the electronics connecting the sensors to a processing unit. The glove naturally must not impede the surgeon's hand mobility, hence the use of a 3D printed auxetic pattern design to maintain full range of motion. The membrane also must function as a secure attachment point for the external sensors as well as allowing the glove to be sterilized for continuous use.

Knowledge of electronics and programming was necessary to achieve the intended functions of the glove. Sensors required power and data transfer through wiring embedded in the membrane connected to a processing unit. The wearable processing unit (WPU) is the brain of the glove, providing power to the sensors, data storage and displaying information on the user's forearm.

Proficiency in prototyping and testing methods were also essential in delivering a usable product. Destructive testing of various high-performance fabrics at different thicknesses, such as Dyneema fibre, found a balance between cut proofing, hand mobility and finger dexterity for the glove itself.

Full in-depth report available upon request