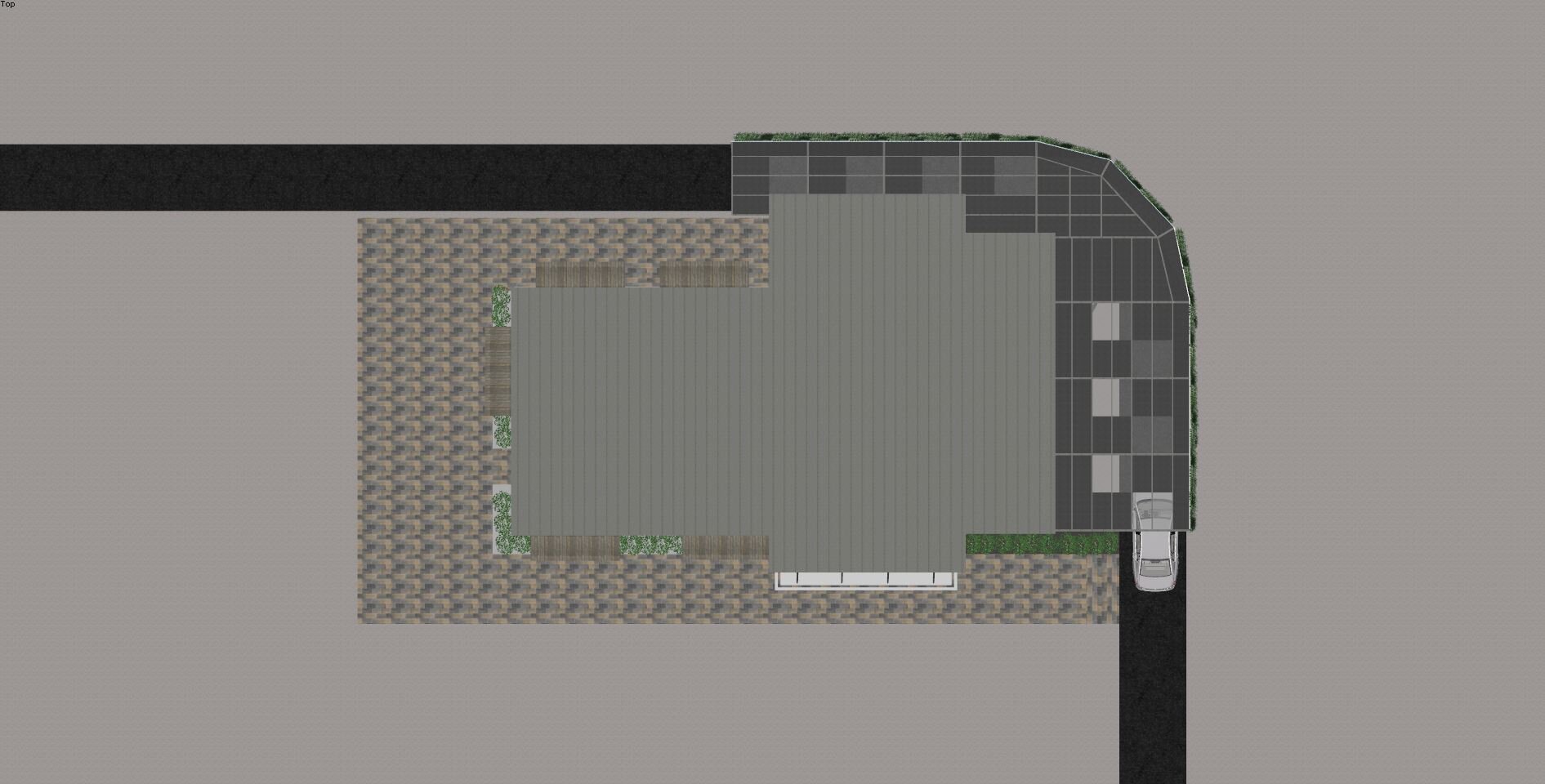

Sound-insulating Drive-through Tunnel

3M

Commercial Design

This materials engineering project proposed by 3M focuses on creating an innovative acoustic insulating system for a fast-food drive-through restaurant. The primary aim was to reduce noise originating from customers and vehicles travelling through the tunnel, particularly during the night.

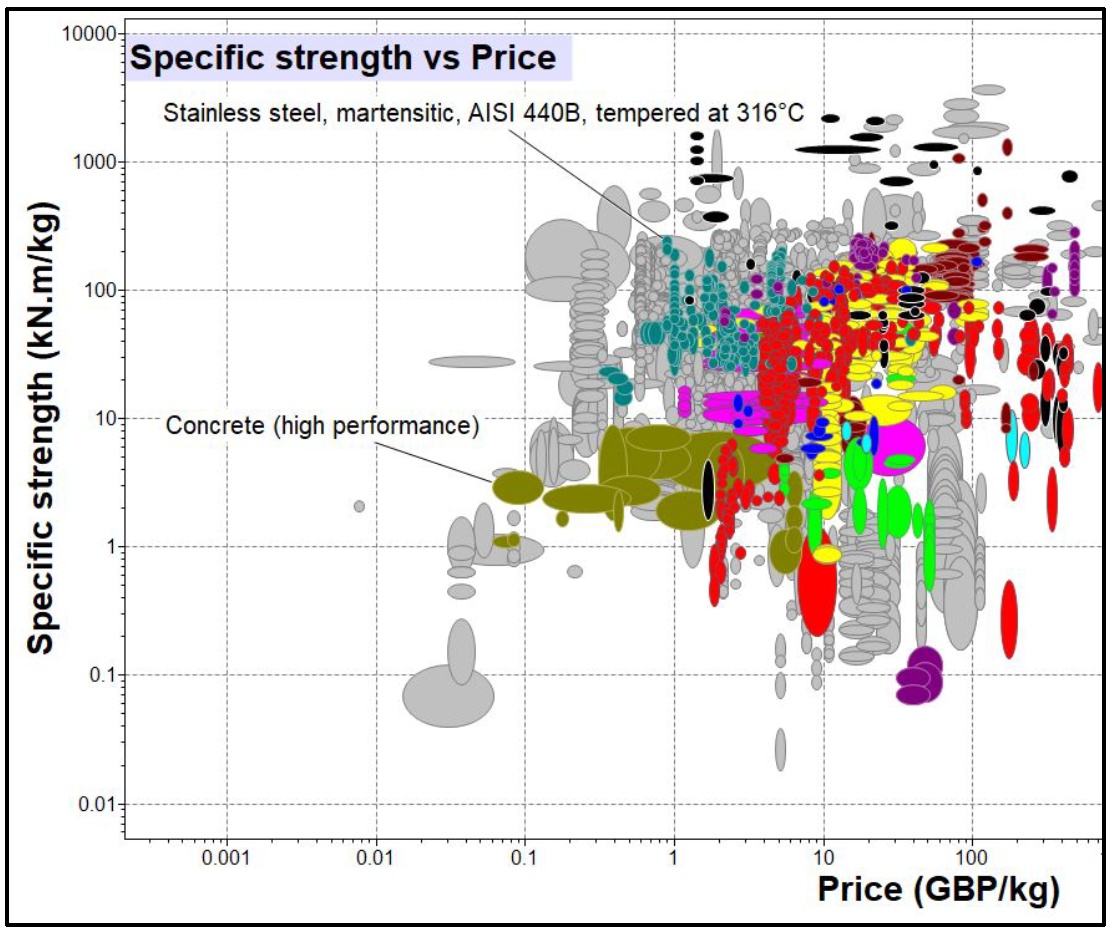

This project utilises suitable sound-absorbing and soundproofing materials selected using CES software to limit disturbance from cars and people ordering at the drive-through. Particular attention was given to the ease of construction of the tunnel, which was designed in modular panels to customise the structure for different restaurants. As a practical solution, factors such as cost, sustainability, durability, safety regulations, air ventilation and aesthetic properties were all considered.

Skill development: Materials Engineering, Construction, CAD, Presenting

The proposed solution is a fully enclosed tunnel built from a sound-absorbing and soundproofing material sandwich.

Sound-absorbing materials have a porous structure capturing and preventing mid to high-frequency sound waves from reflecting off a surface. A Sound-absorbing Recycled Glass Ceramic Foam is used in the interior of the tunnel to prevent sound from reverberating inside the tunnel. Rubberised Open-graded Asphalt on the road surface also helps absorb sound from tyres and the engine, dissipating it through the surface.

Soundproofing materials block sound waves, particularly low frequencies, from passing through the tunnel walls. These materials are usually high in mass. Mass Loaded Vinyl (MLV) is a high-mass, flexible material to prevent soundwaves from passing through the tunnel walls. In comparison to stiff materials, flexible materials suppress sound waves better through damping. A Carbon-reinforced concrete layer was proposed for structural purposes, whilst also providing additional soundproofing.

A viscoelastic soundproofing glue adheres the layers together whilst further providing noise reduction through damping improving low-frequency sound absorption by up to 10dB.

The combination of layers forms a modular panel that fastens to a High-strength Stainless Steel support structure. In the tunnel construction, panels would be cut to shape depending on their location in the tunnel. Materials were chosen based on cost and performance, with maintenance and construction costs both taken into account. A verticle garden along the tunnel walls provides a more visually appealing appearance, and glass windows set in neoprene gaskets allow natural light to enter the tunnel.